Unlocking Efficiency with Simulation Modelling

Unlocking Efficiency with Simulation Modelling

At Prime Design Projects, we’ve been helping businesses design, optimise and future-proof their processes for nearly 30 years. One of the most powerful tools we use to do this is simulation modelling.

What is Simulation?

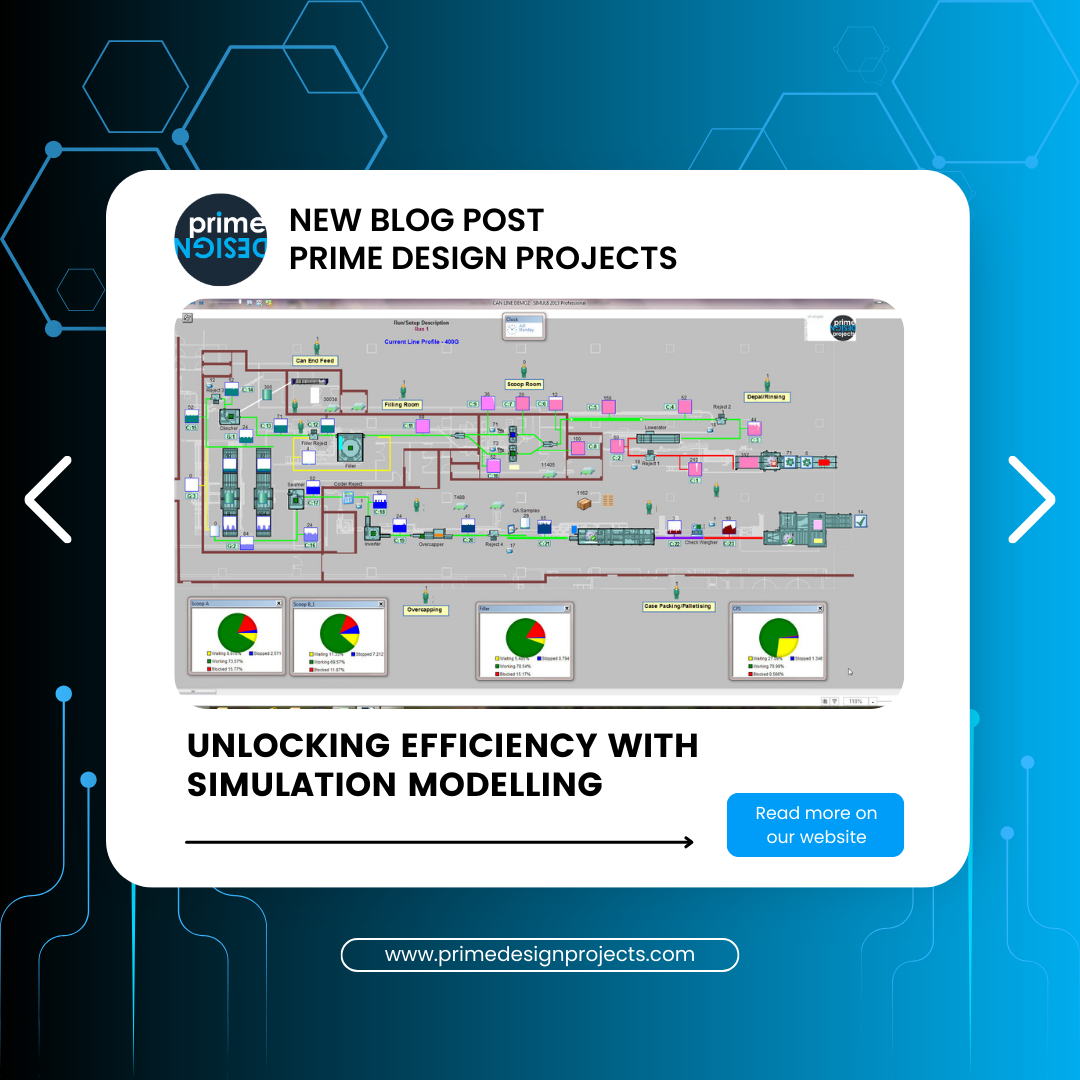

Simulation is a simplified digital representation of real-world events. By replicating a process virtually, it allows businesses to test, analyse and refine their operations in a risk-free environment.

If it can be described and defined, it can be simulated. Think of:

- Airline check-ins and supermarket checkouts

- Production and assembly lines

- Supply chain and logistics systems

The beauty of simulation is that it gives you the ability to experiment, without the cost, disruption or risks of trial and error in the real world.

Why Businesses Use Simulation

Simulation is widely used across industries including manufacturing, automotive, pharmaceutical, healthcare and logistics. As a certified Simul8® Solution Provider, Prime Design brings decades of experience in applying simulation to real business challenges.

Whether you’re solving an existing problem or developing a new process where no prior data exists, simulation enables you to:

- Improve decision-making early in the design phase

- Test multiple scenarios quickly, compressing days of runtime into minutes

- Reduce costs by evaluating designs before capital investment

- Benchmark supplier deliverables with clarity

- Account for future uncertainties and variables

- Align stakeholders with a shared, visual understanding of the process

- Reduce risks by comparing alternatives before implementation

In short, simulation empowers organisations to make informed, evidence-based decisions with confidence.

Real-World Applications

We regularly integrate simulation into our complete filling and packaging line design process, covering everything from raw material supply to warehouse delivery. This ensures inefficiencies are spotted and eliminated, before they impact operations.

Some of our recent simulation projects include:

- Optimising a new high-speed canning line

- Proof of concept for a packaging machine design

- Design evaluation and critique of a 300 cpm canning line in the USA

- Assembly line simulation for a premium UK car manufacturer

- Proposals for line design improvements at a UK dairy

Why Choose Prime Design?

With almost three decades of hands-on experience, we don’t just build models, we build confidence. Our clients benefit from solutions that are:

✅ Efficient

✅ Cost-effective

✅ Backed by evidence and clear analysis

We’re proud to help businesses make the right decisions, the first time.

📩 Email: info@primedesignprojects.com

📞 Phone: +44 (0)1784 668188

Learn more about our simulation expertise: https://www.primedesignprojects.com/Products/Details/18